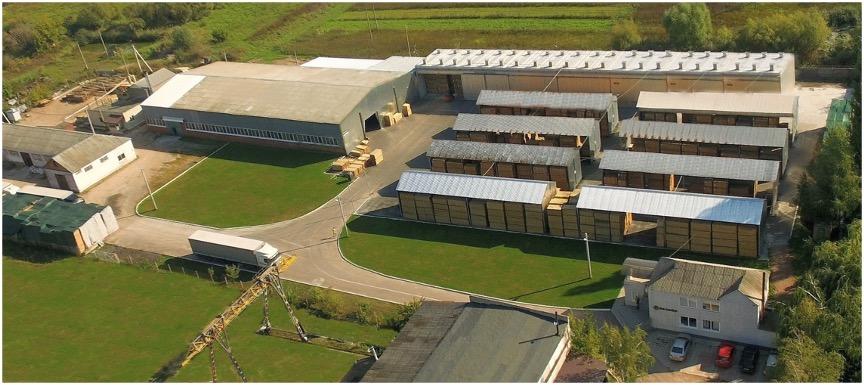

The Rolle group has more than 15 years of experience in purchasing lumber in the Ukraine. We have our own concentration yard since 2009. From there, we work together with over 60 sawmills to create a annual production that exceeds 7.500m³.

Rollé could have not done it alone. At Uro-Lumber there is a dedicated team of 60 employees who helps to improve our quality standards and regular supply.

Uro-Lumber has new computer controlled dry kilns. These kilns are controlled in the Netherlands by our dry-engineer. In the Ukraine we dry our products to a moisture content of 8% - 10%, just like at the facility in the Netherlands. However customized MC is also possible. In our warehouse in Ukraine every board is graded after drying. This is done according to our strict premium grading rules.

In The Ukraine we have a production hall where we can machine our products into semi-finished products. This production includes lamellas, planed boards, shiplaps and tongue and groove.

In the following video, you'll witness the process of locally sourced wood. Upon arrival, each piece undergoes thorough inspection before entering the kiln for drying. Once properly kiln-dried, the wood is graded and sorted into the appropriate bundles

The process of transforming wood into lamella before it's prepared for transport involves several steps aimed at ensuring the wood is appropriately shaped, sized, and packaged for efficient shipping and further processing.